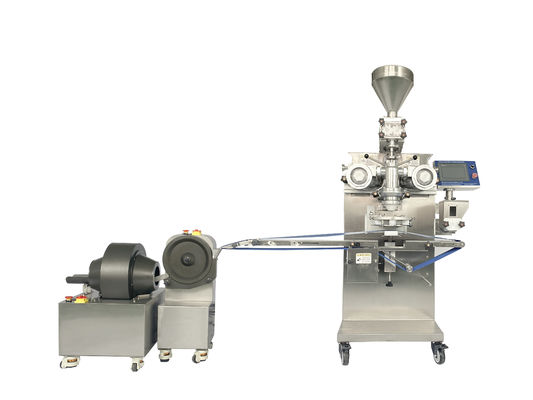

A customer from Lithuania planned to produce date balls and raised an important concern during the initial discussion:their raw material was quite hard, and they were worried that the machine might not be able to process it properly.

The customer first considered testing a machine locally. However, due to strict factory access policies in Lithuania, local manufacturers did not allow external personnel to enter their factories, making local trials impossible.

To fully address the customer’s concern, we proposed a practical and reliable solution:

The customer sent their raw materials to China

We arranged a test run strictly according to the customer’s own recipe

During the test, our machine handled the hard raw materials smoothly, with stable forming performance and consistent product appearance. The complete testing process and results were shared with the customer, giving them full confidence in the machine’s capability.

The customer was very satisfied with the test results.Based on their production target of 120 date balls per minute, we recommended and supplied two complete production lines to meet their capacity requirements.

This successful cooperation demonstrates how real material testing and customized solutions help customers make confident purchasing decisions.

Customer Background & Challenges

Customer Name: Pet Food Company, Australia Business Nature: Specializing in the development and production of high-end natural pet foodCore Product: Additive-Free Chicken Breast Dog Food (100% natural formula, no preservatives or artificial additives)

Pain Points

Low Production EfficiencyReliance entirely on manual operations resulted in a daily output of only 500 kg with 8 workers, making it difficult to achieve scale.

Poor Product ConsistencyHandmade production led to significant variations in the shape, size, and weight of dog food, damaging the brand's premium image and consumer trust.

Severe Capacity ShortageInability to meet the growing order demands from mainstream Australian pet retail chains (e.g., Petbarn, Petstock), frequently causing stockouts.

High Hygiene and Quality Control RisksMultiple manual handling steps increased the risk of cross-contamination and failed to comply with Australia's stringent food safety standards

Difficulty in Cost ControlLabor costs accounted for as much as 45% of total production costs, continuously squeezing profit margins.

Customer Testimonial

“We insist on using only Australian free-range chicken breast with absolutely no preservatives or artificial ingredients. However, the inefficiency of traditional manual production has severely constrained our growth—every month, we are unable to fulfill a significant number of orders on time, which is both frustrating and concerning.”

Automated Production Line Enabling Efficient Transformation

To address Customer's challenges, we customized a fully automated additive-free chicken breast dog food production line, which includes:

Precision Temperature-Controlled Extrusion System: Low-temperature processing preserves the nutrition and natural flavor of the chicken.

Automatic Forming and Cutting Module: Ensures highly consistent weight and shape for every piece of dog food.

Enclosed Conveyor Design: Eliminates human contact throughout the process, preventing cross-contamination.

Trial Results Highlights

Efficiency LeapDaily production capacity increased from 500 kg to 2.5 tons, achieving a 400% efficiency improvement.

Cost OptimizationLabor requirements reduced from 8 workers to 2, lowering the labor cost share from 45% to 15%.

Quality Control UpgradeProduct weight variance controlled within ±1%, with shape consistency reaching 98%.

Full Compliance with Hygiene StandardsPassed Australian food safety audits and received SQF certification recommendation.

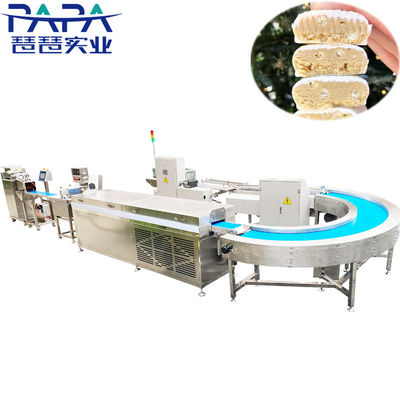

Customer Background : Challenge: Rapidly Establishing a Reliable Production Line to Seize Market OpportunitiesAn ambitious new food factory in Latvia aimed to produce high-quality filled protein bars with chocolate coating to enter the fast-growing healthy snack market. Their core challenge was: how to efficiently establish a complete production line from scratch while ensuring product quality and process stability, enabling them to quickly respond to market opportunities.

Decision-Making Process : Trust Built on Witnessed Success: Friend's Experience Accelerated the DecisionDuring the initial project phase, the client learned through their professional network that a friend's factory had already adopted our identical filled protein bar chocolate coating line in 2024, with the equipment running stably and delivering high output. This firsthand testimony from a trusted partner provided the strongest possible endorsement of our equipment's quality and reliability. Built on this solid foundation of trust, the client engaged in efficient and in-depth technical and planning discussions with our team. After just one month, the client completed a comprehensive evaluation and made the decisive purchase, ordering the complete production line.

Solution and Results : Smooth Delivery and Successful Commissioning: Efficient Production Launch Achieves GoalsOur project team responded promptly, coordinating manufacturing and logistics. The complete production line arrived on schedule at the client's factory in Latvia in November 2025. Under the guidance of our professional engineers, the equipment was smoothly installed, debugged, and operational training was conducted. The line successfully commenced trial operations in a short timeframe. The produced filled protein bars met all design specifications in terms of filling consistency, chocolate coating quality, and production efficiency. This enabled the client to immediately begin small-batch production, laying a solid foundation for their product launch plan.

Customer Value Summary : Why Choose Us: The Complete Cycle of Speed, Trust, and Proven Results

Verified Reliability: The proven operational performance from an existing client was key to eliminating doubts.

Exceptional Decision-Making Efficiency: From detailed negotiation to payment and order placement in just one month, helping the client capture the market window.

Seamless Production Launch Experience: Quick installation and successful commissioning ensured the client's investment rapidly translated into production capacity.

Focused Solution: A mature production line specifically designed for filled protein bar chocolate coating processes, guaranteeing product quality.

After a year of global research, a renowned Macedonian food company, has finally established a strategic partnership with Shanghai Papa to custom-develop the world's first "cooling-coconut powder coating-chocolate coating" double-coated energy bar production line. This innovative production line successfully overcomes technical challenges in multi-layer coating processes, demonstrating the exceptional capabilities of Chinese manufacturing in the field of customized food equipment.

Client Pain Points: Special Process Meets Technical BarriersThe Macedonian client required an extremely unique production process:

Initial cooling and setting of the base bar

Even spraying of coconut powder interlayer

Precision secondary chocolate coating

Final cooling and packaging

"We consulted several European equipment manufacturers, but none could achieve this complex process," stated the Production Director "It wasn't until we met Shanghai Papa that their professional solution won us over."

echnical Innovation: Breakthrough Four-Stage ProcessThe custom solution developed by Shanghai Papa's engineering team includes:

Pre-cooling System: Independent temperature control ensures optimal coating condition

Powder Spraying Device: Patented design achieves uniform coconut powder coverage

Double-Layer Coating Technology: Sequential powder and chocolate coating

Intelligent Temperature Control: Precise temperature parameter management

Core Technical Highlights✓ Precision Powder Spraying: Innovative electrostatic adsorption technology increases coconut powder adhesion rate to 95%✓ Interlayer Bonding Technology: Ensures perfect integration between powder and chocolate layers✓ Energy-Efficient Cooling Design: Two-stage cooling system reduces energy consumption by 30%✓ Intelligent Control System: Fully automated process with one-touch recipe switching

Client Testimonial"This production line completely exceeded our expectations," the client reported. "Shanghai Papa not only understood our unique needs but also turned them into reality through technical expertise. We can now produce uniquely double-coated energy bars that stand out in the market."

About Shanghai PapaShanghai Papa has been focused on R&D and manufacturing of food machinery equipment for 20 years, with products exported to over 60 countries and regions worldwide. The company Always adhere to technological innovation as its core, providing customized food production solutions for global clients.

Challenges Faced

Customer encountered the following production bottlenecks during rapid development:

Manual production line inefficiency unable to meet market demand

Poor product consistency affecting brand image

Continuously rising labor costs

High equipment stability requirements due to South American climate

Production Manager Carlos Rodríguez stated:"Our order volume grew 200% in 2022, but outdated equipment severely limited our development. We needed solutions that could both adapt to Chilean conditions and ensure stable output."

Solution

Equipment Configuration:

Fully automatic protein bar production line Papa P110

Capacity: 3,600 bars/hour

Spanish operation interface support

Special moisture and rust protection treatment

Results Demonstration

Quantifiable Outcomes:

Daily production increased from 8,000 to 20,000 bars (+150%)

Product qualification rate improved from 92% to 98.5%

Labor costs reduced by 60%

Production energy consumption decreased by 25%

Client Testimonial:"This production line not only solved our capacity issues but, more importantly, ensured product quality stability. The cost-performance ratio of Chinese equipment completely exceeded our expectations."

Technical Highlights

Adaptability Improvements:

Moisture-proof design for South American climate

Spanish operation interface

Localized technical service support

Local procurement solution for vulnerable parts

Smart Features:

Recipe memory system

Fault self-diagnosis

Remote maintenance support

Data traceability system

Market Impact

Industry impact from this collaboration:

Became benchmark case for health food equipment upgrades in Chile

Generated 3 new client purchases in South America

Enhanced reputation of Chinese manufacturing in Latin American markets

Ongoing Collaboration

Based on initial success, ProteinPower plans to:

Add second production line

Co-develop specialized recipes

Become demonstration factory in Chile

A renowned Argentine ice cream supplier with six retail locations has successfully overcome technical challenges in developing energy ball products through an in-depth collaboration with our company. After the client's special visit to our Chinese factory for a two-day technical exchange, they expressed high satisfaction with our professional capabilities and plans to purchase a complete energy ball production line.

Client Background and ChallengesThis Argentine ice cream enterprise enjoys a strong brand reputation and stable customer base in the local market. To expand their product line, the company decided to develop new energy ball products but faced the following challenges:

Lack of knowledge in energy ball production formulas and processes

No experience in operating relevant equipment

Unclear about product quality control standards

Need for complete production line solutions

The client stated: "We excel in ice cream production but have no experience in the entirely new field of energy balls. We needed a partner who could provide not just equipment, but complete technical solutions."

Solution and Implementation ProcessAfter two months of detailed communication, the client decided to personally visit our factory in China. Our technical team developed a comprehensive technical exchange plan:

Online Technical MeetingPrior to the client's arrival, we organized a 2-hour online meeting to deeply discuss core technical aspects of energy ball production with the client and their engineering team.

On-site Technical Training

Formula development guidance: Shared multiple energy ball formula solutions

Equipment operation demonstration: Showcased the complete process from raw materials to finished products

Quality control training: Taught methods for controlling key process parameters

Customized Production Line SolutionBased on client needs, we recommended the most suitable equipment combination:

Mixer: Achieves uniform mixing of ingredients

Filling Encrusting Machine: Ensures precise filling encapsulation

Rounding Machine: Forms perfect spherical shapes

Coating Machine: Provides even chocolate coating

Inclined Conveyor: Enables seamless process connection

Small Coating Machine: Meets special coating requirements

Cooling Tunnel: Ensures perfect product setting

Packaging Machine: Completes final product packaging

Results and FeedbackThe client stated at the conclusion of the visit: "This trip to China exceeded our expectations. Not only did it solve our technical challenges, but it also filled us with confidence in energy ball production. We will immediately issue the equipment purchase contract upon returning home."

ShangHai Papa machine recently successfully assisted a US home-based mochi producer in solving chocolate coating production challenges. By recommending our smallest 8kg chocolate coating machine, the client achieved product upgrading within limited space and budget, obtaining satisfactory results.

Client Background & ChallengesThis California-based client operates a small mochi workshop with limited space and no additional staff. As the business grew, the client wanted to develop new products by coating traditional mochi with chocolate to enhance taste and value. However, manual coating methods were not only inefficient but also produced inconsistent appearance, seriously affecting product quality and sales.

The client stated: "I tried hand-coating with chocolate, but the results were never ideal. It was time-consuming and labor-intensive, and the finished products didn't look professional. As a small workshop, I neither have space for large equipment nor sufficient budget for big machines or additional staff."

Customized SolutionAfter thoroughly understanding the client's needs, the technical team at shanghai papa machine recommended the 8kg chocolate coating machine, most suitable for small-scale production. This equipment features:

Compact design, occupying only 0.5 square meters

Simple operation, manageable by a single person

Precise temperature control ensuring even, smooth chocolate coating

Cost-effective with high value for money

Implementation ResultsAfter receiving the equipment and simple operational training, the client immediately began production. Results showed:

300% increase in production efficiency (40 minutes vs previous 2 hours)

Professional-looking products with even, glossy coating

Improved chocolate utilization, reduced material waste

No need for additional staff, saving labor costs

The client excitedly reported: "This small machine completely transformed my production model. Now I can easily coat mochi with chocolate, and the products look like they came from a professional dessert shop. Most importantly, it perfectly adapts to my small workshop environment - simple to operate and easy to clean."

Equipment Advantage AnalysisThe success of the 8kg chocolate coating machine demonstrates its unique value in small-scale food production:

Space-friendly: Designed for limited spaces

Economical & practical: Fast ROI, suitable for startups

Easy operation: No professional training required

Quality assurance: Achieves professional-grade coating results

Flexible production: Meets small-batch, multi-variety needs

Industry SignificanceThis case proves that small food producers can also achieve product upgrades and process improvements through suitable equipment. The Product Manager at shanghai papa machine stated: "We always believe that good equipment shouldn't only serve large enterprises. This 8kg coating machine is specifically designed for small entrepreneurs, making technological innovation accessible to more food producers."

About shanghai papa machineShanghai papa machine is committed to providing innovative solutions for global food producers. From home-based workshops to large factories, we offer the most suitable equipment choices. Our product line covers production needs of various scales, always adhering to the "most suitable is best" product philosophy.

I. Customer Background and NeedsA emerging health food company in the U.S. planned to quickly enter the chocolate ball market and sought a supplier capable of customizing equipment and delivering within 15 days. The customer had consulted multiple companies but was turned down due to the tight timeline. They urgently needed a reliable partner to help them seize market opportunities.

II. Customer Concerns and Challenges

Tight Timeline: Industry standard delivery periods typically range from 30-45 days, making 15 days highly challenging.

Lack of Trust: The customer was skeptical about the supplier's ability to achieve customized production in such a short time.

Quality Risks: Concerns that shortening the delivery period would compromise equipment precision and stability.

III. Solutions and Trust-Building

Rapid Response and Commitment:

Clearly communicated the ability to meet the 15-day delivery requirement and provided a customized solution.

Case Studies and Reputation Verification:

Immediately shared successful customized case studies from local U.S. customers (including equipment videos, contract excerpts, and customer feedback).

Provided contact information of local customers for direct verification.

Transparent On-Site Verification:

Invited the customer for an online video tour of the factory, showcasing real-time production line operations, warehouse material reserves, and R&D workshops to demonstrate rapid response capabilities.

Highlighted how modular design enables customized production within short cycles.

Technical Details Confirmation:

The engineering team worked overnight to align technical parameters (e.g., chocolate viscosity, molding precision requirements) and delivered a detailed technical solution within 48 hours.

IV. Results and Achievements

Successful Contract Signing: The customer arranged full payment the next day, and the contract officially took effect.

On-Time Delivery: Equipment production, testing, and packaging were completed on the 15th day and shipped to the U.S. via air freight.

Customer Feedback:

"The equipment's operational efficiency exceeded expectations. The chocolate ball molding precision reached ±0.5g, fully complying with FDA standards. Your speed and professionalism are impressive!"

Long-Term Cooperation Intentions: The customer explicitly stated that they would prioritize purchasing our packaging and coating equipment for future expansion.

Machine working video:https://youtu.be/twbhK3DFBLo?si=a3PZzrn1GlQ8AurI

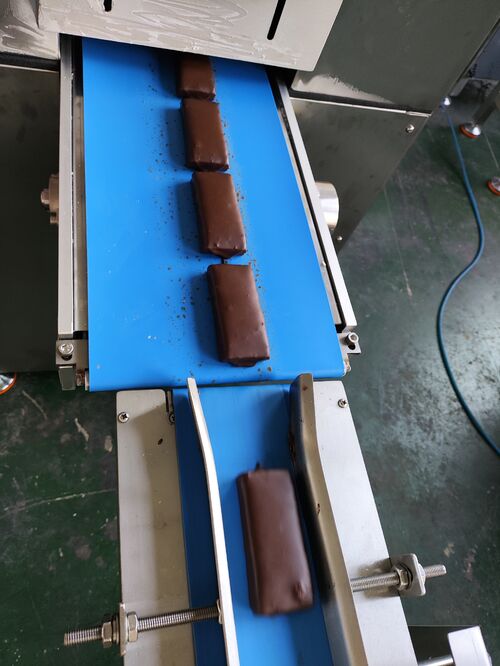

Client Background:A health food manufacturer in Argentina had been producing traditional energy bars using existing equipment for years. However, as market trends shifted toward thinner, more refined products, the client faced significant challenges.

Challenges:

Existing equipment produced uneven cuts and poorly finished product surfaces.

Inability to handle sticky ingredients efficiently, leading to low production productivity.

Limitations in product thickness made it impossible to produce the trending 6mm thin energy bars.

Competitors' thin energy bars were gaining increasing market share.

Solution:We provided the client with an innovative production solution:

Cooling Before Cutting: A specialized cooling tunnel was used to bring the energy bar mixture to an optimal state for cutting.

Precision Cutting System: Custom-designed cutting tools ensured smooth and clean cuts, even for sticky mixtures.

Precise Thickness Control: Equipment parameters were fine-tuned to achieve stable production of 6mm ultra-thin products.

Integrated Production Line: A complete solution from forming, cooling, and cutting to packaging was provided.

Implementation Process:

Shared successful case studies of projects in Argentina and other countries.

Provided detailed technical proposals and equipment performance parameters.

Facilitated direct communication between the client and existing customers.

Customized the design to meet the client’s specific requirements.

Results and Value Delivered:

Technical Breakthrough: Successfully achieved stable production of 6mm ultra-thin energy bars.

Quality Improvement: Products exhibited smooth and even cuts, significantly enhancing their visual appeal.

Efficiency Boost: Production efficiency increased by 40%, while the defect rate decreased by 60%.

Competitive Edge: The client launched competitive products and captured a larger market share.

Fast Delivery: The project was completed and delivered within just two months.

Client Feedback:“Your company provided not just equipment but a comprehensive solution. Your technical expertise and rapid response impressed us deeply.

If you are facing similar production challenges, feel free to contact us for a professional solution. With a proven track record of global success cases, we provide the most suitable production equipment and technical support for your needs.